Before you know it, the edges of your beautiful tiles may start coming apart and cracks will form if you do not use the correct adhesive. But, a strong one can make your tiles stay secure for years to come.

The best adhesive for vitrified tiles depends on its size, the surface you are tiling on and where they will be placed. Cement-based adhesives work well for standard installations, while epoxy adhesives provide stronger bonds for high-traffic areas.

Many homeowners also explore modern options like adhesive floor tiles or premixed solutions, which make the process faster and easier.

So, let’s break down the key factors that will help you pick the perfect adhesive for a lasting, flawless finish.

What Are Vitrified Tiles?

Vitrified tiles are crafted by combining silica, clay, quartz and feldspar and then exposing the mixture to intense heat in a kiln. The outcome of this process is a sturdy, dense tile with low water absorption, making it exceptionally durable.

Why Use An Adhesive?

An adhesive is an expertly created product to provide a stronghold, ensuring tiles stay firmly fixed on floors, walls and other surfaces. It is the bond between tile and adhesive which guarantees the longevity of your installation, even when exposed to extreme conditions.

Choosing the right material, whether ceramic adhesive, tile glue adhesive, or even a specialized waterproof tile adhesive, can be the difference between a short-lived project and one that lasts for decades.

The adhesive should be able to withstand heavy foot traffic, moisture and other influences that could affect the tiles over time. If the tiles are not properly bonded, they can shift or leave unsightly gaps that might also pose a safety risk.

Contractors often recommend floor tile cement in 20kg tile adhesive packs, as these are economical yet effective for large flooring projects.

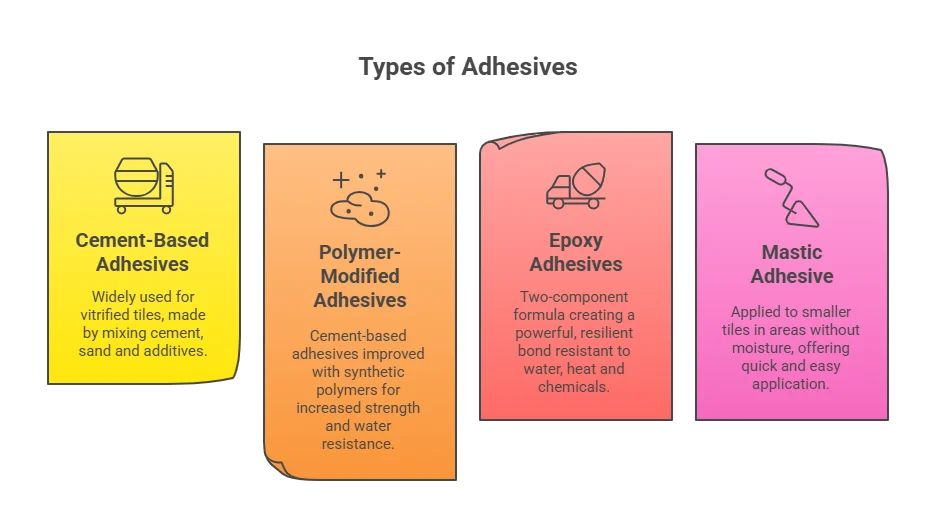

Types Of Adhesives

-

Cement-Based Adhesives

Cement-based adhesives are the most widely used adhesive for vitrified tiles. These adhesives are made by mixing cement, sand and additives to achieve a paste-like consistency.

Cement-based adhesives need to be applied to a smooth, clean surface before placing vitrified tiles for the best grip.

These adhesives are dependable for general applications and work well for most residential tasks. However, in areas with high humidity or constant use, they might not perform as you expect.

-

Polymer-Modified Adhesives

Polymer-modified adhesives are cement-based adhesives that are improved with the addition of synthetic polymers. The adhesive’s strength, flexibility and water resistance increase significantly with these additives, which are great for vitrified tiles.

Polymer-modified adhesives provide the strength and durability needed to keep your vitrified tiles stable even under challenging environments.

For bathrooms or wet zones, using a shower tile adhesive or ready mixed floor tile adhesive ensures strong bonding while keeping the surface waterproof.

-

Epoxy Adhesives

Epoxy adhesives type involves a two-component formula: one part resin and the other part hardener. Together, these elements produce a powerful, resilient bond that resists water, heat as well as chemicals.

These adhesives are highly valued for their superior bonding power, which is why they are so commonly used in industrial and commercial settings. They are also ideal for situations where tiles need to endure heavy stress.

In fact, epoxy adhesive glue is widely used as a swimming pool tile adhesive because of its unmatched resistance to water pressure and chemicals.

-

Mastic Adhesive

Mastic adhesives are usually applied to smaller tiles in areas that do not deal with moisture or humidity. These adhesives are not the strongest out there, but when you need something done quickly, they will work just fine.

Many DIY homeowners prefer mastic adhesive or tile on tile adhesive when installing wall backsplashes or refurbishing old tiled areas.

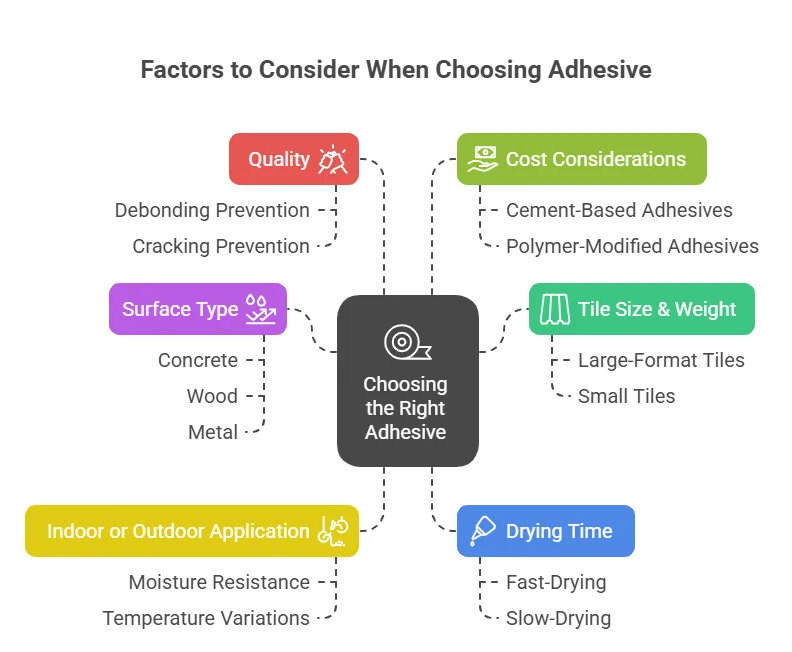

Factors To Consider When Choosing The Right Adhesive

Tile Size & Weight

The size selection for vitrified tiles is extensive. It covers everything from small mosaic patterns to grand, large-format tiles. A tile’s weight and dimensions play a key role in determining which adhesive will work best.

A high-performance adhesive or one with extra bonding power is necessary to ensure a secure hold for bigger tiles. Those include polymer-modified and epoxy adhesives.

Since smaller tiles do not require as much bonding power, a basic cement-based adhesive should be enough. Larger format porcelain pieces, however, perform best with a porcelain tile adhesive or a modified thinset that offers stronger grip.

Surface Type

Your adhesive needs to be compatible with the surface you are tiling as well. From concrete to metal, vitrified tiles can be installed on a range of surfaces, such as cement, plaster and wood.

And, different materials demand different adhesives for maximum bonding strength. Concrete or cement surfaces are generally more porous and can hold onto adhesives better.

A strong yet flexible cement-based adhesive is what you need for these surfaces. Because wooden and metal surfaces lack porosity, a polymer-based glue will stick effectively. On delicate surfaces like plasterboard, a modified thinset or flooring tile adhesive works better than traditional cement.

Both plaster and drywall are sensitive to water, which can make them difficult to manage. A fast-setting adhesive is ideal for such surfaces, helping you avoid premature bonding issues.

Indoor Or Outdoor Application

You should also consider the setting where you will lay the tiles. When installing things in a kitchen or bathroom, look for an adhesive that can stand up to moisture.

Areas subjected to them benefit from using epoxy or polymer-modified adhesives, whereas for indoor applications with less exposure to external factors like temperature and humidity, cement-based adhesives are more suitable.

Dry backsplashes and walls can be mounted with mastic adhesives. Make sure the adhesive you select for outdoor environments can deal with temperature variations and UV rays. For exterior projects, outdoor tile adhesive or heat resistant tile adhesive provide long-term durability against weather changes.

Epoxy adhesives offer superior protection against the elements, making them a prime choice for outdoor vitrified tile applications.

Drying Time

The amount of time it takes for the adhesive to dry can impact how quickly and well your tiles are installed. Based on your project’s schedule, you might prefer an adhesive that dries faster or one that allows more time for adjustments.

Perfect for when you are pressed for time, fast-drying adhesives bond in just a few hours. With slow-drying adhesives, you can make adjustments and reposition tiles without feeling rushed. However, you will have to wait longer before grouting the tiles.

Quality

A quality adhesive is fundamental for vitrified tiles. It ensures a strong tile installation that stands the test of time. High-quality adhesives are engineered to provide a lasting bond attaching the vitrified tiles and the substrate.

Opting for a subpar adhesive may cause problems later on, like tiles debonding, cracking or even the complete failure of the tile installation. Investing in the best tile adhesive saves you from future headaches like debonding, cracking, or replacing tiles.

Cost Considerations

Finding the right adhesive means balancing performance and cost, so your budget matters too.

Cement-based adhesives offer a more economical choice, but they might not function as efficiently as more expensive adhesives like those modified with polymers or made from epoxy. Bulk purchases such as tile adhesive 20kg bags or economy packs of floor tile cement are often chosen for larger commercial flooring projects.

So, reflect on the goals of your project and think about how investing in a high-quality adhesive could pay off in the long run.

And, that concludes everything for this blog post. We sincerely hope this gave you the clarity and knowledge you were looking for. We at Lakshmi Ceraamics are sending you our best wishes for a successful tiling project!

Step-by-Step Tile Installation Guide with Adhesive

Installing vitrified tiles with the right adhesive ensures long-lasting performance. Here’s a simple DIY-friendly process:

-

Surface Preparation – Clean and level the surface; remove dust, grease, or loose particles.

-

Mixing the Adhesive – For powder adhesives, mix with water (or recommended additive) until smooth and lump-free.

-

Application – Spread adhesive evenly using a notched trowel for uniform thickness.

-

Tile Placement – Press tiles firmly into place, ensuring proper alignment and spacing.

-

Curing & Drying – Allow adhesive to set (usually 24 hours) before grouting to ensure strong bonding.

Best Adhesive by Area

Choosing the right adhesive depends on where the tiles are installed:

-

Kitchen & Bathroom → Polymer-Modified or Epoxy Adhesive (resistant to water, heat, and chemicals).

-

Outdoor Patios & Balconies → Epoxy Adhesive (withstands weather, moisture & heavy load).

-

Living Room & Hallways → Cement-Based or Polymer-Modified Adhesive (durable and cost-effective).

-

Backsplashes & Wall Tiles → Mastic Adhesive (ready-to-use, ideal for vertical applications).

For specialized needs, a swimming pool tile adhesive or a shower tile adhesive provides long-lasting protection in wet areas, while a resistant tile adhesive is ideal for kitchens and fireplaces.

FAQs

Q1. Can I use normal cement for vitrified tiles?

No. Normal cement does not provide the required adhesion and may cause tiles to pop out. Specialized tile adhesives are recommended.

Q2. Which adhesive is best for outdoor vitrified tiles?

Epoxy adhesive is best for outdoor areas since it is water-resistant, weatherproof, and highly durable.

Q3. How much adhesive is required per sq. ft.?

On average, 3 - 4 kg of tile adhesive is required per sq. meter (approx. 0.3 - 0.4 kg per sq. ft.), depending on tile size and thickness.

Q4. Can epoxy adhesives be used on walls?

Yes, epoxy adhesives can be used for wall tiles in wet or high-stress areas, though mastic is more common for backsplashes.

Q5. How long should tile adhesive cure before grouting?

Typically, 24 hours of curing is required before grouting, but check the manufacturer’s instructions for best results.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to customercare@lakshmiceramics.in

|

Mr. Ram S +91 96551 70955 |

|

Mr. Martin +91 78688 86655 |

We will love to hear from you!